Introduction:

Artificial intelligence (AI) has developed exponentially within the past decade, with a seemingly boundless run of capabilities and potential. Essentially, AI is the science of educating machines how to think and it’s quickly forming businesses over the globe.

AI has started to play a critical part in our everyday lives, from domestic collaborators like Alexa to healing centers distinguishing ailments. Its integration into systems and processes in manufacturing opens the door to numerous possibilities. It can boost efficiency, upgrade effectiveness, and clear the way for development. These are all potential diversion changers and AI is as of now making its stamp on the industry.

Here, we’ll delve into the role of AI in Manufacturing Industry, exploring how artificial intelligence is shaping processes and driving innovation is changing the industry, changing traditional methods and opening up a wealth of opportunities for the future.

The Role of AI in Manufacturing: Harnessing the Power of Artificial intelligence in the Industry

AI has become a powerful tool in manufacturing, improving efficiency over the entire process from supply chain to quality control. Its journey began in the 1980s with knowledge capture, clearing the way for more profound integration in recent years. Nowadays, AI helps in everything from design and production to quality checks and logistics, shaping the future of manufacturing.

AI’s Impact in Manufacturing

AI integration in manufacturing yields

- Cost reduction

- Boosts supply chain efficiency

- Enhances product quality.

It enables

- Predictive maintenance

- Optimizes production schedules

- Improves defect detection rates, leading to significant improvements across the board.

Uses Cases of AI in Manufacturing Industry

AI is broadly utilized in the manufacturing industry. These are some of the foremost noticeable use cases of AI in the manufacturing industry:

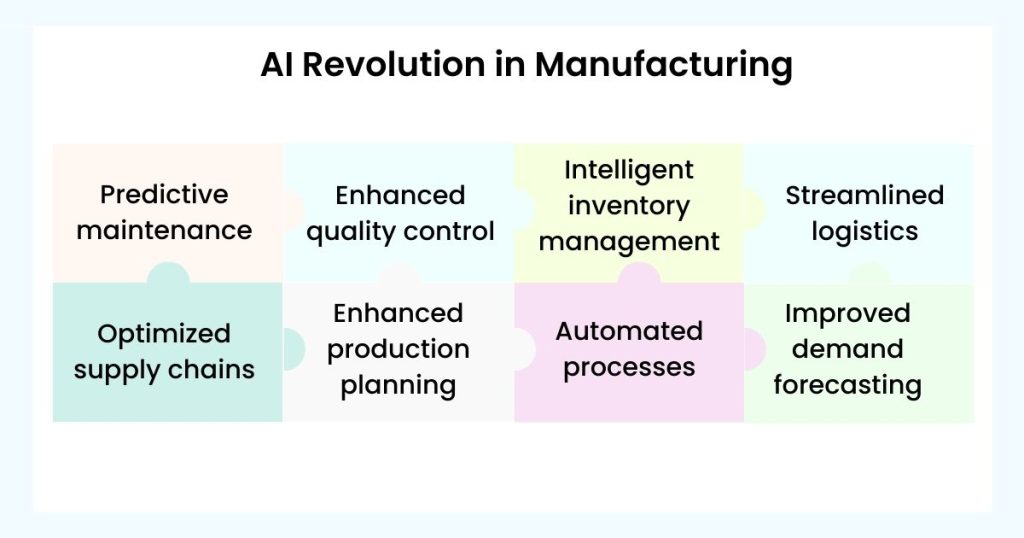

AI Revolutionizes Manufacturing From Quality Control to Production Planning ,AI is quickly transforming the manufacturing landscape offering plenty of benefits.

- Predictive maintenance: AI Analyses sensor data to foresee and avoid equipment failures before they occur, minimizing downtime and boosting productivity.

- Enhanced quality control: AI-powered image recognition inspects products with 90% higher precision, guaranteeing consistent quality and reducing costs.

- Intelligent inventory management: AI predicts demand trends and optimizes stock replenishment, minimizing lost sales and stock order errors.

- Streamlined logistics: AI analyses traffic patterns to propose ideal routes and forecast delays, driving to faster deliveries and lower fuel consumption.

- Optimized supply chains: AI predicts supply chain disruptions and optimizes demand forecasting, allowing manufacturers to build more productive and resilient systems.

- Enhanced production planning: AI analyses historical data to recognize designs and patterns, empowering optimized production schedules and resource allocation.

- Automated processes: AI automates repetitive tasks, increasing productivity, reducing errors, and improving safety.

- Improved demand forecasting: AI analyses data to predict future demand with higher precision, permitting businesses to create way better decisions based on real-time insights.

These are just a few cases of how AI is as of now making waves within the manufacturing industry. As AI innovation proceeds to advance, we will anticipate even greater advancements and a future of increased proficiency, improved quality, and enhanced competitiveness for manufacturers worldwide.

Impact of AI in Manufacturing Industry: A Landscape Transformation with Real-World Examples

Artificial intelligence (AI) has rapidly infiltrated the manufacturing sector, transforming traditional methods and driving significant advancements. Here’s a glimpse into some of the key areas currently experiencing the impact of AI, along with real-world examples:

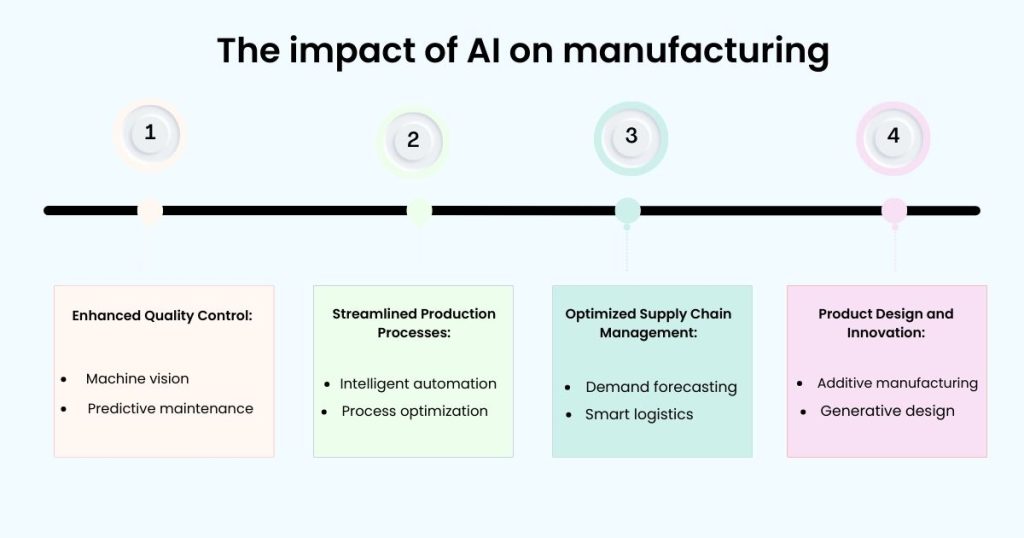

1. Enhanced Quality Control:

- Machine vision:

Example: BMW uses AI-powered machine vision to inspect car parts for defects with 99.5% accuracy, significantly surpassing the capabilities of human inspectors.

- Predictive maintenance:

Example: GE Aviation utilizes AI to analyze sensor data from jet engines, predicting potential failures with high accuracy. This allows airlines to schedule maintenance proactively, minimizing downtime and ensuring the safety of passengers.

2. Streamlined Production Processes:

- Intelligent automation:

Example: Ford employs AI-powered robots to weld car frames with greater precision and efficiency compared to traditional methods. This not only improves product quality but also increases production speed.

- Process optimization:

Example: Honeywell leverages AI to analyze data from its factories, identifying inefficiencies in production lines. Based on these insights, they optimized the layout and scheduling, resulting in a 20% increase in production output.

3. Optimized Supply Chain Management:

- Demand forecasting:

Example: Unilever utilizes AI to forecast demand for their products across various regions. This information helps them optimize production planning and inventory levels, reducing the risk of stockouts and minimizing storage costs.

- Smart logistics:

Example: DHL employs AI-powered logistics solutions to optimize delivery routes based on real-time traffic data and weather conditions. This leads to faster deliveries and reduced fuel consumption, contributing to cost savings and environmental sustainability.

4. Product Design and Innovation:

- Generative design:

Example: Autodesk utilizes AI to generate innovative designs for aircraft wings that are lighter and more fuel-efficient than traditional designs.

- Additive manufacturing (3D printing):

Example: Siemens utilizes AI to optimize support structures for 3D-printed parts, minimizing material waste and reducing production time.

These are just a few examples of how AI is already transforming the manufacturing landscape. As AI technology continues to evolve, we can expect even more groundbreaking advancements that will redefine the future of manufacturing.

AI in Manufacturing: A Glimpse into the Future

Artificial intelligence (AI) has already revolutionized the manufacturing industry and its impact is only accelerating. As we peer into the future, here are some exciting trends on the horizon:

1. Autonomous Vehicles Take the Wheel:

Imagine self-driving vehicles not only zipping around factory floors but also handling deliveries between facilities. This isn’t science fiction; it’s the future of autonomous vehicles (AVs) in manufacturing.

- Benefits: 24/7 operation, reduced accidents, smoother material flow, and a streamlined production process.

Example: Imagine a fleet of AVs autonomously transporting parts between different production lines within a factory, ensuring a continuous and efficient workflow.

2. AI Goes Green:

Sustainability is becoming a top priority and AI is stepping up to the challenge. We can expect to see AI:

- Minimize waste: Optimize production processes to reduce material consumption and scrap generation.

- Optimize energy consumption: Analyze energy usage and suggest efficiency improvements for equipment and facilities.

- Design eco-friendly products: AI-powered tools can analyze materials and suggest sustainable alternatives, leading to the creation of environmentally friendly products.

Example: An AI system monitors a factory’s energy consumption in real-time, identifying areas where adjustments can be made to reduce energy waste and optimize production.

3. Chatbots Become Your AI Companion:

Chatbots are already assisting with employee training and troubleshooting, but their future looks even brighter.

- Personalized Learning: Imagine chatbots tailoring training modules to individual learning styles and needs.

- On-demand Support: Chatbots can provide 24/7 assistance to employees, answering questions and resolving issues in real-time.

- Bridging the Gap: Chatbots can facilitate communication between humans and machines, translating complex technical data into understandable language.

Example: A new employee on the factory floor can access a chatbot for on-demand training on operating a specific machine, receiving step-by-step instructions and troubleshooting tips.

Challenges and the Journey Forward:

While these advancements are promising, challenges remain:

- Cost and complexity: Implementing advanced AI solutions can be expensive and require specialized expertise. This necessitates flexible financing options and investments in upskilling the workforce to bridge the skills gap.

- Data security and privacy: Utilizing vast amounts of data necessitates robust data security measures and adherence to data privacy regulations. Manufacturers must prioritize transparency and ethical development throughout the AI implementation process.

- Human-AI Collaboration: As AI automates tasks, it’s crucial to ensure human-centric approaches. This includes fostering trust and acceptance, providing collaboration training, and ensuring humans hold meaningful roles in the future of manufacturing.

By acknowledging and addressing these challenges, manufacturers can pave the way for a future where humans and AI work together, creating a more efficient, sustainable, and prosperous manufacturing landscape.

Conclusion:

Artificial intelligence (AI) offers transformative potential for manufacturing, enhancing productivity, quality, and profitability. As AI evolves, its role in manufacturing will grow, automating tasks and refining quality control. It’s crucial to deploy AI responsibly, ensuring it benefits both workers and society, creating a prosperous and sustainable future for all.